Techniks USA - Spinner Deburring Machine Case Study

Maximizing Production Efficiency: Case Studies on the Techniks Spinner Deburring Tool

In high-precision industries, deburring is not just an optional step—it's essential for ensuring product safety, assembly accuracy, and overall quality. The Techniks Spinner Deburring Tool has proven itself as a standout solution, delivering measurable improvements in efficiency, cost reduction, and product finish. Let’s explore real-world success stories that highlight its transformative impact across various sectors.

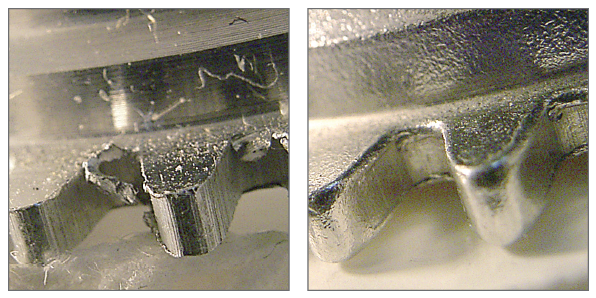

Case Study 1: Aluminum Gears

Dimensions: 1 9/16″ diameter x 5/16″ high

Challenge: This manufacturer faced challenges deburring soft aluminum gears with irregular shapes. Burrs were left in multiple gear gaps, and rough edges compromised the quality and functionality of the parts.

Solution: The company utilized the Techniks Spinner Deburring Tool to address the burrs effectively. Its self-adjusting blade was particularly useful in navigating the irregular contours of the gears.

Deburring Time: 10 minutes

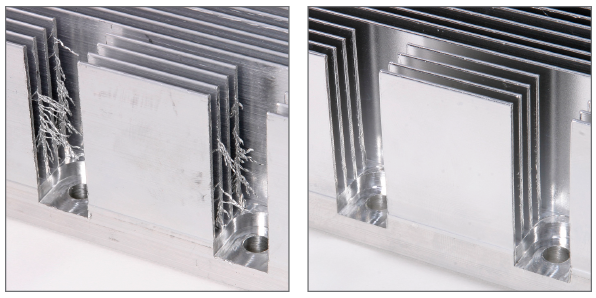

Case Study 2: Aluminum Cooling Fins

Dimensions: 4.75″ x 2.125″ x 2.75″

Challenge: Long burrs and rough edges plagued these soft aluminum cooling fins, particularly in the multiple thin slits that required delicate handling.

Solution: With the Techniks Spinner Deburring Tool, the manufacturer achieved consistent, burr-free finishes without damaging the fins’ thin structures.

Deburring Time: 15 minutes

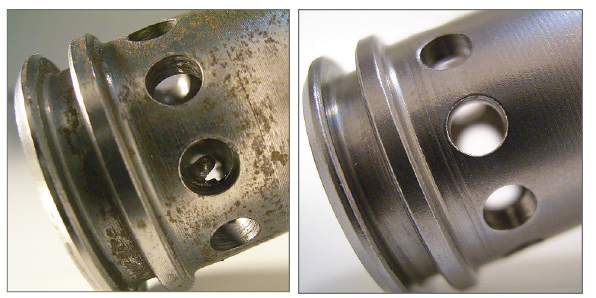

Case Study 3: Stainless Steel Turned & Machined Part

Dimensions: 3/4″ diameter x 1 7/16″ long

Challenge: A compact stainless steel cylinder posed deburring difficulties due to its rusty surface and burrs in multiple cross-drilled holes.

Solution: The Techniks Spinner Deburring Tool efficiently removed burrs while maintaining the part’s structural integrity, even in challenging cross-drilled areas.

Deburring Time: 20 minutes

What These Case Studies Prove

The Techniks Spinner Deburring Tool is more than just a tool—it’s a solution that enhances productivity, quality, and cost-efficiency. Across industries, businesses have reported tangible improvements, including:

- Faster production times

- Lower rejection rates

- Enhanced workplace safety

- Improved customer satisfaction

Why Choose the Techniks Spinner Deburring Tool?

- Automatic Adjustment: Delivers consistent results on materials of varying thicknesses.

- Replaceable Carbide Blade: Ensures long-lasting precision and easy maintenance.

- Ergonomic Design: Lightweight and easy to handle, reducing operator fatigue.

- Durable Construction: Built to withstand demanding industrial environments.

Drive Results in Your Business

The results are clear: investing in the Techniks Spinner Deburring Tool can lead to significant improvements in efficiency, quality, and cost savings. Whether you’re in automotive, aerospace, or metal fabrication, this tool delivers the reliability and performance your business needs to stay competitive.

Ready to transform your production process? Contact us at sales@ldewitt.net to learn how we can help you achieve your goals.

Recent Posts

-

Techniks USA - Spinner Deburring Machine Case Study

Maximizing Production Efficiency: Case Studies on the Techniks Spinner Deburring ToolIn high-precisi …Jan 7th 2025 -

The Spinner Deburring & Finishing Machine

Achieve Precision and Efficiency with the Techniks Spinner Deburring ToolIn the world of machining a …Jan 7th 2025 -

Unveiling the SC400 Controller from Bijur Delimon: Your Ultimate Lubrication Solution

In the industrial world, efficient lubrication is paramount to ensuring the smooth operation and lon …Aug 7th 2024